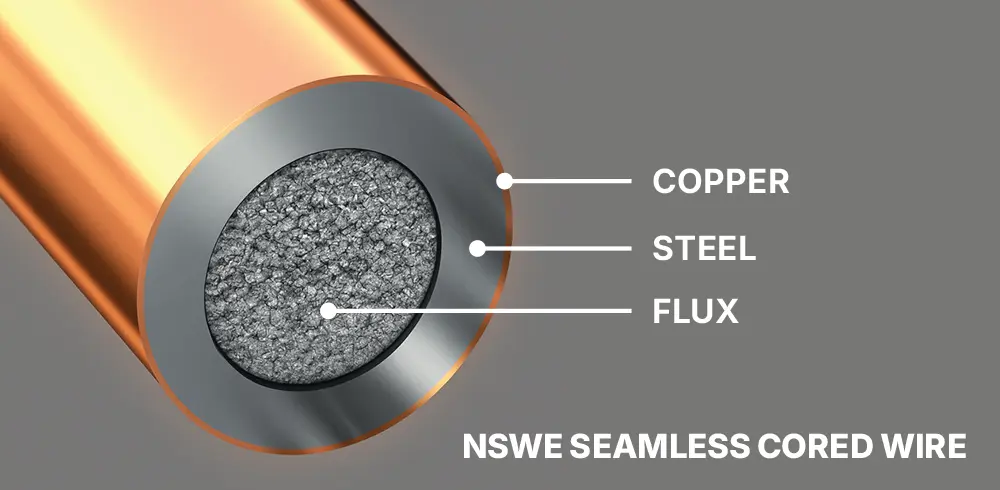

The seamless flux core and metal core welding wires designed and manufactured in Japan by Nippon Steel Welding & Engineering Co., (NSWE), are classic examples of Japanese engineering excellence.

NSWE is a subsidiary of Nippon Steel Corporation, one of the largest steel producers in the world and renowned for their market-leading product development and consistently high quality standards. As a group, they invest heavily in R & D to stay at the forefront of new technologies.

NSWE’S Advanced Manufacturing Method:

- Horizontal flux filling process to achieve even spread of flux ingredients for consistent composition and stable welding. Commonly used vertical filling by vibration results in heavy flux elements moving lower in the wire and uneven composition affecting weld quality.

- High Temperature dehydrogenation and seam welding ensures very low diffusible hydrogen.

- Exactly engineered drawing and shaping of the wire for perfect cross-sectional symmetry.

Low Hydrogen Content: Low diffusible hydrogen levels reduce the risk of porosity and cold cracking, improve weld quality and reduce pre- and/or post-heating requirements. The very low levels in NSWE seamless wires are maintained over time, even after storage and opening.

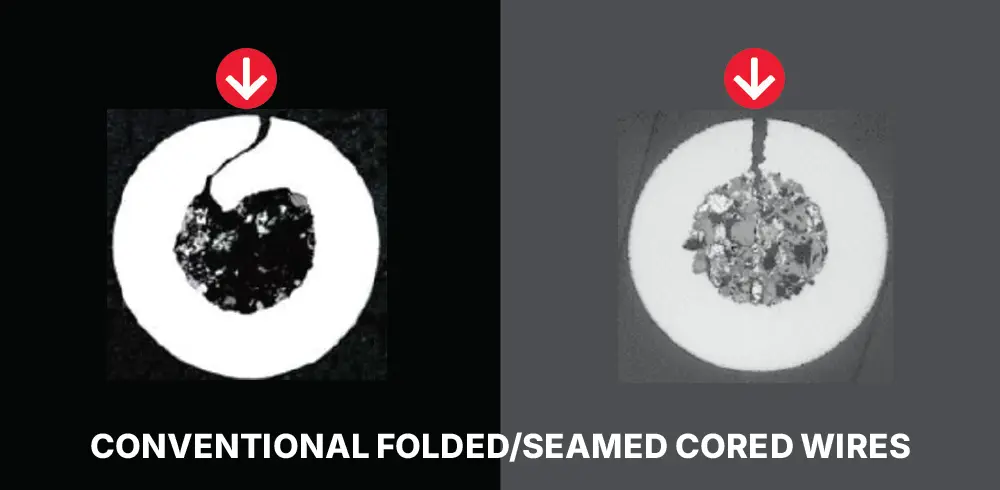

Improved Performance: The wire’s perfect symmetry and seamless design ensure smooth, consistent feeding with no catching or oscillation. The copper coating enhances electrical contact. These features ensure precise targeting and a very stable arc, giving better penetration and fusion with less heat.

Reduced Wear: The seamless design and copper coating means minimal friction. No lubrication is required so no residue build-up, and wear on liners and tips is reduced by as much as 80% compared to seamed wires. NSWE seamless wires are so smooth that they are run with V-groove drive rollers; knurled rollers are not required.

Enhanced Productivity: The very stable arc and smooth wire feeding combined with reduced downtime for consumable replacement and troubleshooting, significantly increases welding efficiency and productivity.

Superior Durability & Corrosion Resistance: With no seam for moisture/hydrogen to enter, the low hydrogen content remains steady even in humid or damp, cold conditions. The copper coating protects against corrosion and oxidation over time.

Consistent High Weld Quality: NSWE seamless wires consistently produce quality welds with excellent mechanical properties. Re-work is minimised; production is maximised.