WENZL visited the Schweissen & Schneiden International Welding & Cutting Trade Show in Germany, where Cobot welding and fume extraction took centre stage.

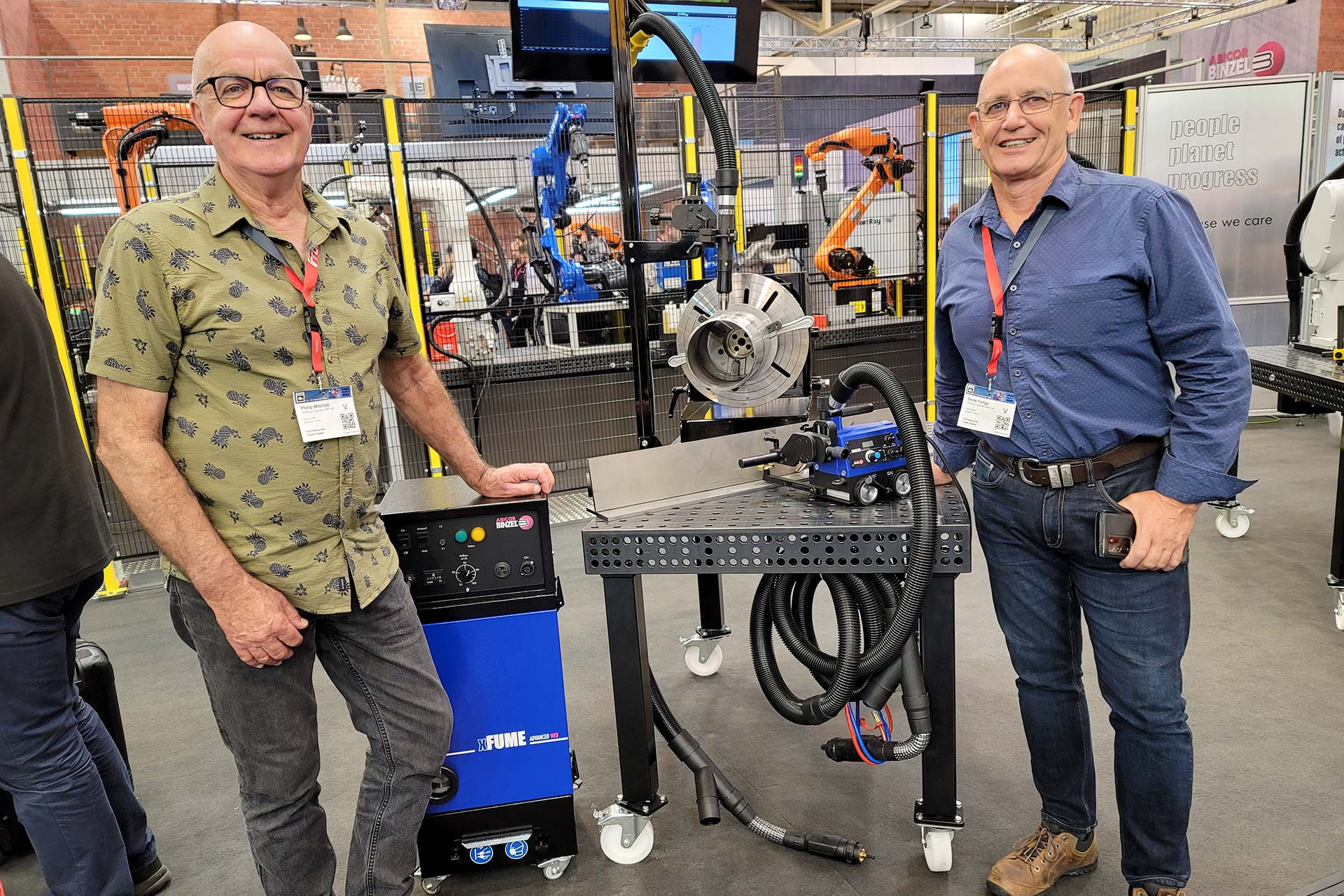

Derek and Phil visited the Schweissen & Schneiden International Welding & Cutting Trade Show held in Essen, Germany, in September. With 826 exhibitors from around the world, a virtual who’s who of the industry was on display and the show offered a fantastic overview of the innovations and trends in the industry.

Welding Cobots

A marked difference from the previous show in 2017 was the large number of welding Cobots on display, undertaking a range of functions. LORCH remains the market leader in welding cobots, showcasing their second generation UR10e Cobot, which was mounted on a linear axis extending both reach and versatility.

The UR10e Cobot has Cobotronic software options which are impressive; SeamTracking weld correction which automatically keeps the Cobot on the course of the weld seam regardless of deviations, distortion, or poor fit-up.

SeamPilot, which utilizes a line laser on the welding torch bracket to make programming the Cobot and ensuring the perfect weld even easier. Just show the Cobot a rough starting point, the line laser sensor will find the weld seam and guide the Cobot to the detected end point. This will enable automatic welding of difficult courses in curves, waves, or circles, poor fit-out pieces, even variation in repeated jobs. The welder simply determines the desired result – SeamPilot will do the rest.

Welding Fume Extraction

Fume extraction technology was also heavily promoted at Essen this year. Many stands were utilising mechanised on-torch extraction, some OEM, and a number utilising Abicor Binzel extraction torches. Multi-torch systems which are installed in large workshops are becoming more common. To learn more, check out the ABICOR BINZEL Fume Extraction Torch.