Welding Products

Nippon Steel Speciality Steels

Coastal Weathering Steel

Steel for Bridge High Performance Structures (SBHS)

Nippon Steel Corporation is the third largest steel producer in the world. They invest heavily in R & D and have developed a number of speciality steels for specific needs. As Japan is very similar geographically and seismically to New Zealand, Nippon Steel speciality steels often have direct applicability here.

Coastal Weathering Steel

Nippon Steel has developed two types of corrosion-resistant, weathering steels which can be used in New Zealand in C4-C5 corrosion zones; NAW-TEN (Nickel added) and CORSPACE (Tin added).

While conventional steel girders are lightweight and provide flexibility in design and construction; ongoing painting and maintenance add to whole-of-life costs. Weathering steel plate, which does not require painting, has all the advantages of steel design with much reduced maintenance, lower life cycle costs, and less environmental impact.

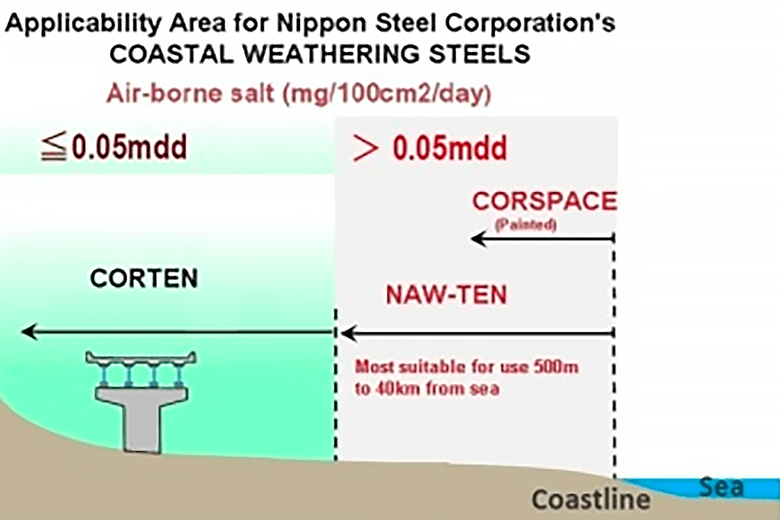

The use of conventional weathering steel, e.g. CORTEN, is limited to areas away from the sea as exposure to NaCl salts in the atmosphere affects the formation of the protective patina or “rust” layer and increases corrosion of the steel.

Generally, conventional weathering steel can be used in locations that are more than 2km from the open seacoast, however, this minimum safe distance may increase up to 40km, depending on prevailing wind strength and direction, ocean wave and coastal surf conditions, topography, obstructions to wind flow and the level of shelter near the actual site.

As NZ is a long, narrow, seismically active country with many main roads and rail following the coastline, this significantly limits the use of CORTEN-type weathering steels. Japan is geographically very similar to NZ and faced the same problem.

To overcome this restriction, Nippon Steel Corp. developed Ni-Added and Sn-Added Coastal weathering steels with modified chemical formulations which are specific to the Nippon Steel products, trade names NAW-TEN and CORSPACE.

NAW-TEN develops a rust-like protective patina over time and does not need painting.

CORSPACE is a COrrosion Resistance Steel for PAinting Cycle Extension. The formulation which includes Tin (Sn), prevents the steel from promoting corrosion when the paintwork is scratched or damaged in the severe corrosive environment close to the sea.

Steel for Bridge High Performance Structures (SBHS)

SBHS (Steel for Bridge High Performance Structures) are high-performance, high-tensile strength steels developed to reduce the construction costs of steel bridges.

High strength, up to 700 N/mm 2, and uniformity of yield strength regardless of thickness allow for reduced steel in weight and wider spans. In addition, the SBHS steels are easier to work with; reduced or nil preheating is required, welding heat input can be higher, and cold bending work is improved.

SBHS steels are available in conventional weathering steel specifications and as CORSPACE, Sn-added advanced weathering steel.

Reducing the weights of steel bridge structures through the use of SBHS with superior yield strength is considered an effective means not only of improving the earthquake resistance of bridges but also of helping to build a sustainable infrastructure.

10,000 MT of Nippon Steel’s SBHS was used to build the Tokyo Gate Bridge pictured above, completed in 2011, including a 440 metre central span. The use of SBHS reduced total weight by 3% and total construction cost by 12% (estimates by the Japanese Ministry of Land, Infrastructure, Transport and Tourism).