The range of LORCH Mig welding machines is a good example of where synergic control is heading in the Industry 4.0 era.

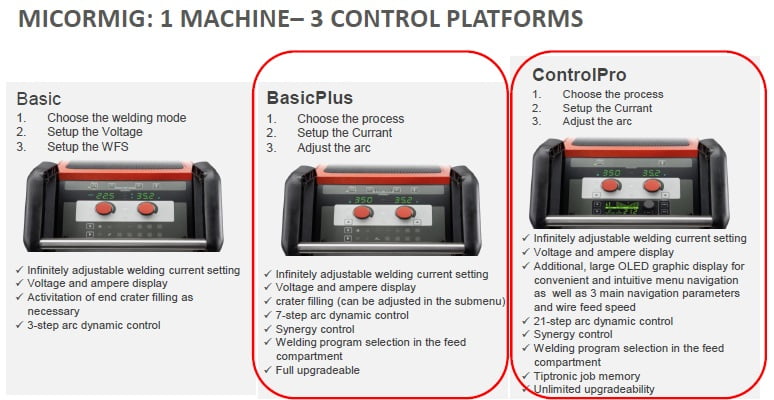

Made in Germany these are highly flexible, modular systems which can be built to order from 300A to 500A outputs, compact or remote wire feed, gas or water-cooled, and with three different operating control panels to choose from.

The Basic panel gives you non-synergic regular control and is not upgradable, think of it as the manual car with a bit of class. The Basic Plus is entry level synergic control which gives you options; dynamic arc control, upgradeable with software programmes and processes, can read NFC cards (like Paywave, a way to control welding parameters, download programmes or jobs), it’s the automatic car with airbags. The Control Pro is fully synergic, upgradeable now and in the future, finely tuned dynamic arc control, large tiptronic memory (here comes the cruise control), can read and write NFC cards, fully recordable, detailed job management – the Tesla SUV without the high price card.

That’s a simplistic way to look at it, but similar technological development to what we have seen in cars, mobile phones, computers, has been paralleled in welding technology in the past 2-3 decades. The ultimate aim is to make quality welding easier, safer, consistent and controllable. Choose your welding machine wisely and it can future-proof your welding operation.