Welding fume is very dangerous to industrial workers. Consisting of metal, process gas and non-process gas, welding fume forms a toxic air contaminant that rises, spreads, and is easily inhaled.

In this article we explain what Source Capture Fume Extraction is, and how it can help minimise the impact of these toxins in your workshop.

The Increasing Awareness of the Dangers of Welding Fume

A study from IARC, the International Agency for Research on Cancer, classified weld fume as a Class I carcinogen in 2017, meaning welding fume is a known cause of cancer. Local and national governments are increasingly enforcing more stringent air quality requirements to protect industrial workers. A cleaner and safer environment not only protects industrial companies from liability, but it helps your workforce be more productive and attracts quality people to your company.

The Closer to the Arc Weld Fume is Captured, the Less it Spreads

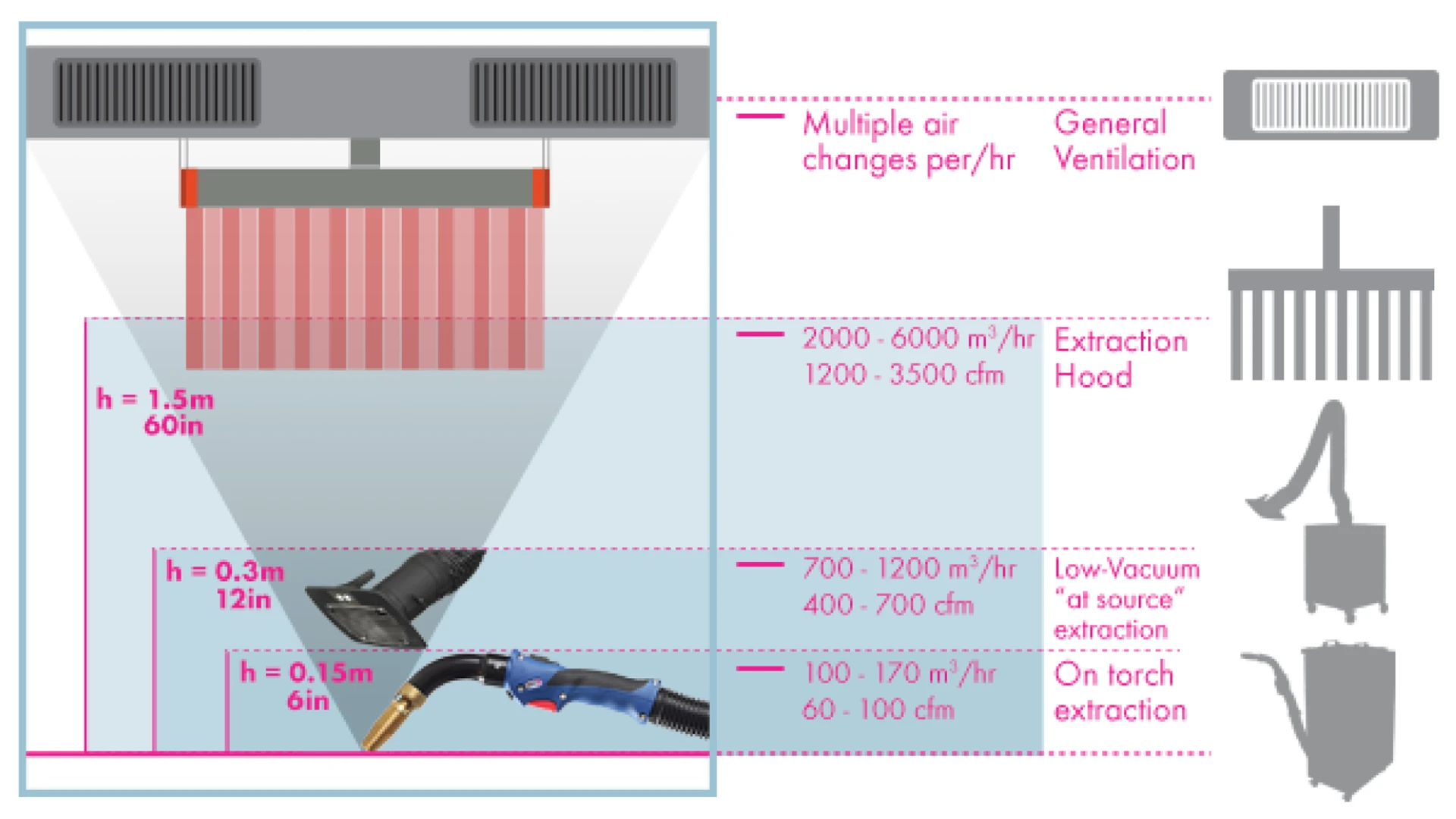

Many of the more well-known fume extraction solutions are positioned far away from the source of the weld fume. These measures do a good job of funnelling out dirty and hazardous weld fume but are not able to protect the welder directly. These solutions extract from a position too far from the worker and the source of weld fume to protect them from breathing in these dangerous fumes. As engineered solutions catch weld fumes closer to where it begins, the ability to limit it’s spread increases.

This is why our solutions focus heavily in the most concentrated areas, where they can make the greatest impact, often at a lower cost.

Weld Fume is Best to Address at the Welding Arc

Fume extraction welding guns are not new technology. But the way they work today is. Modern engineering has allowed us to know more about the type of static pressure needed to effectively capture weld fume depending on your parameters and your welding process.

The more restriction and the higher the parameter = the more suction power you need. This means you need to have an adequate amount of pressure to capture those concentrated weld fumes without affecting shielding gas and without compromising the welder.

The xFUME® Fume Extraction Solutions by ABICOR BINZEL creates opportunity to improve fume extraction safety in a number of welding applications. Fume extraction products for manual and robotic welding operations are available. These solutions are designed to work for you to ensure the role of fume extraction, a necessary addition to every operation, is easy and effective. Extracting at source maximises protection for your welder and will also give protection to other staff who may be exposed to your workshop environment.

Content adapted from Abicor Binzel: https://www.binzel-abicor.com/US/eng/products/fume-extraction-welding/