Ever wondered what is the best welding wire on the market?

Recently one of our technical staff took a sample coil of SM-3A seamless metal cored wire – one of a number of seamless wires from NSWE – to run in a heavy manufacturing workshop. Their feedback says it all. The first run by their lead welder was an effortless flow, crisp sounding, smooth, and no spatter to speak of. The weld was extremely consistent with no clean-up needed. He laid down his torch and said, “we need this wire”. “You like it?” “Very much, this wire is easy, fast, clean. I want this wire.”

NIPPON Seamless Cored Welding Wires

We often talk about the benefits of the extremely low hydrogen content and resistance to moisture pick up of the seamless cored wires produced by NIPPON STEEL WELDING & ENGINEERING CO. (NSWE), but on the factory floor it’s the hassle-free welding that stands out. The very smooth wire feeding and superior conductivity make these wires not only a pleasure to weld with, but also faster, easier, and cleaner than any other wire.

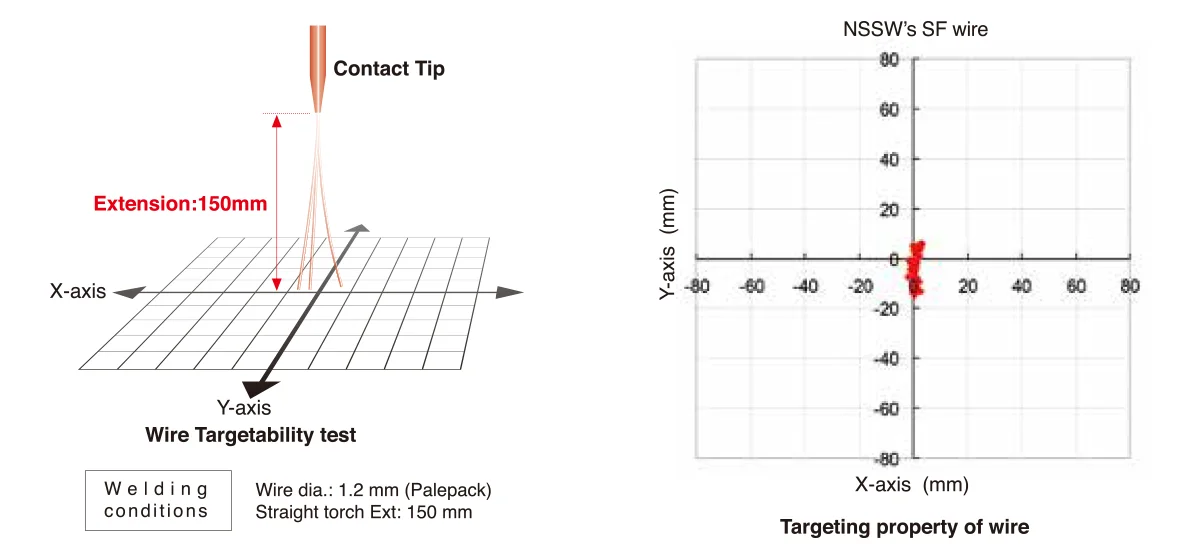

NSWE has a unique manufacturing process in which the wire is horizontally filled, welded and drawn out to the required size, then double copper coated and shaved to ensure a perfectly symmetrical round shape. The meticulous engineering and attention to detail produces wires which feed out smoothly and straight, with stable, accurate targeting at the weld point.

By comparison, many flux cored welding wires are soft, inconsistent in diameter or shape and may have extra lubrication on the wire surface or require knurled rollers to push the wire through. Poor feed-ability, birdnesting, burning back on the contact tip, clogging of the gun liner and excessive tip wear are among the challenges that welders may face with lesser quality wires, especially at high current and wire feed speeds.

The pinpoint symmetry and copper coating of NSWE seamless cored wires also provide optimal current transfer from contact tip to wire for a stable consistent arc.

The reduced friction extends the life of the contact tip and liner, which means less changeovers, less downtime, and lower consumable costs.

Maximising welding performance is essential to improve efficiency. Choosing the best quality seamless cored wire will make your welders’ lives easier at the same time as saving you money with significantly lower labour costs.

Hands down, NSWE’s seamless flux and metal cored wires are the best welding wires on the market. There are various wires available to suit differing welding needs. Make a change for the better – experience the difference with seamless flux and metal cored welding wires from Nippon Steel Welding & Engineering (NSWE). Call Welding Engineers (NZ) Ltd on 09 634 1949 to find out more.

Related Articles

Revealed: Often Overlooked Fact when Reducing Welding Costs

The biggest cost in welding is the wage of the one holding the torch. Using their time efficiently is fundamental to minimising your operational costs.

Hydrogen Cracking – Diffusible Hydrogen and how to avoid it

Hydrogen cracking can occur when welding carbon and low-alloy steels. The potential for hydrogen cracking in the weld metal and HAZ depends on their composition.

Cold Cracking-Low Hydrogen

We have seen several instances of cold cracking in welds when visiting customers. The standard of welding work and adherence to correct procedure was not an issue, so the question was why it occurred and what can be done to avoid a repetition.