Authorised distributors for the world’s best welding wires.

Please note the American Welding Society withdrew the A.36 Classification in 2021 but both old and new classifications may coexist for some time. There have also been changes to some EN ISO classification designations, which may not be correct on manufacturer data sheets as yet. The updated and corrected classification specifications can be found on the top of each wire product page. If you have any queries, please contact us.

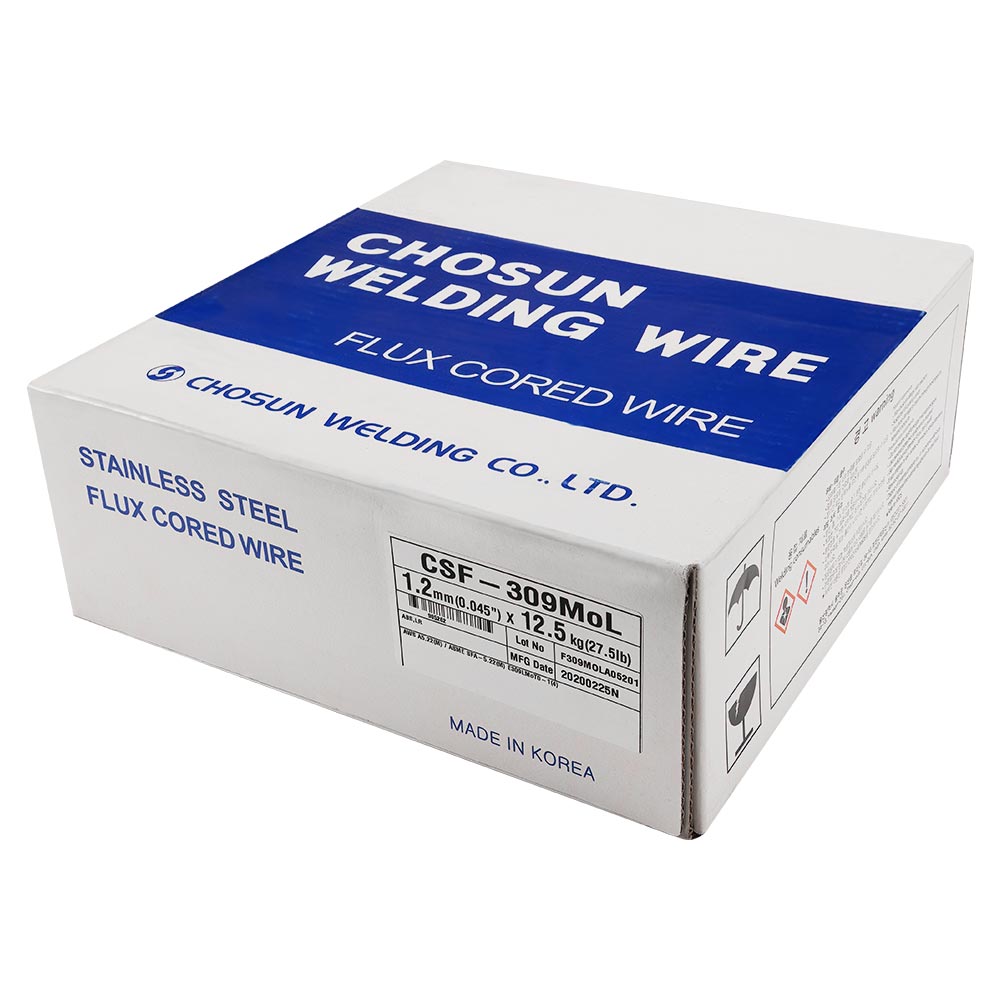

Welding Engineers NZ Ltd is the authorised distributor for Nippon Steel Welding & Engineering Co. Ltd in Australia and New Zealand and the authorised New Zealand agent for Kobelco Welding and Chosun Welding flux cored welding wires.

Wires such as Nippon SF-1E and Kobe DW-100 have been foremost in the New Zealand welding world for many years for good reason. Quality flux cored wires can make welding easier, faster, cleaner, and more efficient with better quality welds.

Why change to a flux-cored wire?

If welding with a solid MIG wire works, why change to a higher priced flux-cored wire?

For almost all welding applications a correctly selected flux cored wire can do the welding job better and faster than a solid wire.

- Higher deposition rates

- Optimised all-positional welding

- Improved sidewall penetration

- More tolerance of poor fit-out, gaps

- Ease of use

- Targeted mechanicals

The flux in the core of flux cored wires combine a number of ingredients which are specific for the welding application or performance enhancement each wire is designed for, e.g. slag formers to shield the weld pool and shape and support the weld, alloys to improve the mechanical properties, fluxing agents to clean up impurities and remove hydrogen on the weld metal.

Flux cored wires can be seamed or seamless and vary in quality. Seamless wires can give advantages in minimising hydrogen, smooth wire feeding, etc.

Optimising the efficiency of the welding job by choosing the best quality flux cored wire will pay off in the overall cost of the job: Faster, cleaner, more efficient, welding with minimal defects will reduce the largest cost component of your work – labour.