Plasma cutting is fast and clean on thin to moderate thickness ferrous and non-ferrous metals, including aluminium and stainless steel. It is typically a much cleaner cut than oxy-fuel, with minimal follow-up work required. A plasma cut also has a very narrow heat affected area, minimizing warping and distortion. As it uses compressed air rather than oxygen, it is also safer for the operator. Easier to control, more accurate for shaping, many can also gouge.

Oxyfuel cutting enables metalworkers to cut even very thick ferrous metals, and a variety of torch options can be used to braze, solder, gouge, preheat, and bend metals as needed. The trade off is that the multi-purpose torches do have a reduced cutting capability compared to single purpose cutting torches, so be clear on what you require the torch to do.

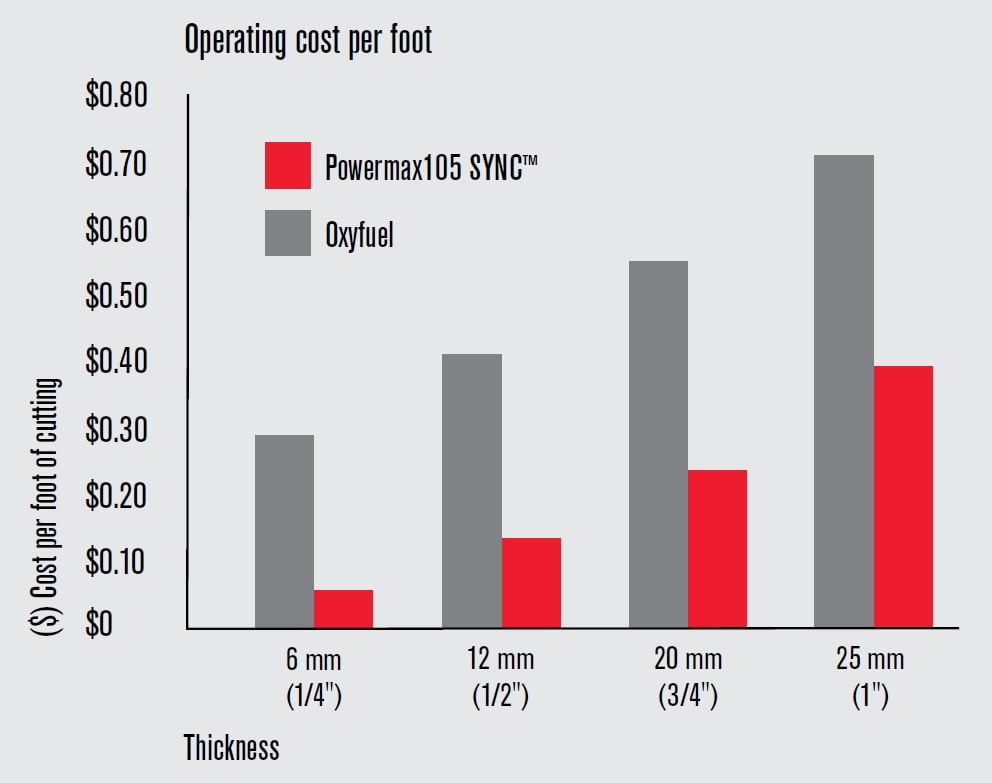

Economics

Depending on the size of the comparative cutting systems, the operating costs can be significantly lower for plasma cutting over oxyfuel.

The initial purchase cost is higher; but choose wisely and invest in a Hypertherm Powermax plasma cutting machine and your upfront costs will be recouped very quickly.

If you’re in the market for a versatile, reliable, quality cutting system, we highly recommend investing in a Hypertherm Powermax machine.